Carbon Fiber Intakes: Revolutionizing Performance Weight Reduction

Carbon fiber intake systems revolutionize vehicle performance by offering a superior strength-to-wei…….

Welcome to an in-depth exploration of carbon fiber intake systems, a cutting-edge technology that has captured the attention of industries worldwide. This article aims to unravel the complexities of these systems, highlighting their significance, applications, and potential. Carbon fiber intake systems represent a significant advancement in material science and engineering, offering unparalleled strength, lightweight properties, and environmental benefits. By the end of this comprehensive guide, readers will grasp the global impact, technological innovations, and future prospects of this remarkable technology.

Definition: Carbon fiber intake systems (CFIS) refer to advanced mechanical systems designed to efficiently capture, process, and utilize carbon fibers—a type of synthetic material composed of carbon atoms arranged in a specific molecular structure. These systems are pivotal in transforming raw carbon fiber into valuable commodities used across various sectors.

Core Components:

Historical Context: The concept of carbon fiber intake systems evolved alongside the growing demand for lightweight, high-performance materials. Carbon fiber itself was first developed in the 1960s, finding early applications in the aerospace industry. As material science advanced, the need for efficient processing methods became apparent, leading to the birth of CFIS in the late 20th century. Over time, these systems have become more sophisticated, driven by the desire for cost-effectiveness and environmental sustainability.

The influence of carbon fiber intake systems extends far beyond borders, shaping industries and economies globally. Here’s a glimpse into its international impact:

| Region | Impact and Trends |

|---|---|

| North America | Known for its advanced automotive industry, North America leads in CFIS adoption for lightweight vehicle components. Companies like Tesla and Ford have embraced carbon fiber, driving innovation in electric vehicle (EV) manufacturing. |

| Europe | With a strong focus on sustainability, Europe is at the forefront of developing eco-friendly CFIS. Countries like Germany and France are home to cutting-edge research institutions, fostering advancements in recycling and upcycling carbon fiber. |

| Asia Pacific | This region’s rapid industrialization has spurred demand for CFIS across various sectors. China, in particular, has emerged as a major manufacturer of carbon fiber, while Japan leads in robotics and automation, enhancing CFIS efficiency. |

| Emerging Markets | Countries like India and Brazil are exploring CFIS to boost local manufacturing and reduce reliance on imports. These regions offer untapped potential for both production and applications. |

Global trends indicate a growing demand for sustainable and lightweight materials, driving the need for efficient CFIS. The push for electrification in transportation and construction is expected to further propel the market’s growth. Additionally, the rise of 3D printing and advanced composite materials will likely shape future CFIS developments.

The economic landscape surrounding carbon fiber intake systems is dynamic and multifaceted. Here’s an analysis of its economic implications:

Market Dynamics:

Investment Patterns:

Industry Impact:

The evolution of carbon fiber intake systems has been characterized by technological advancements that enhance performance, efficiency, and sustainability. Here are some key innovations:

As we peer into the future, several trends and developments will shape the trajectory of carbon fiber intake systems:

Carbon fiber intake systems represent a significant milestone in material science and engineering, offering a path toward a more sustainable and lightweight future. As the world grapples with environmental challenges and the push for advanced materials, CFIS will play a pivotal role in shaping industries and economies. The global impact of these systems is evident, with technological innovations driving efficiency, sustainability, and new applications across various sectors.

As we look ahead, the ongoing evolution of CFIS promises exciting possibilities, from lightweight vehicles and sustainable buildings to advanced aerospace technologies. By embracing these systems and fostering collaboration, humanity can unlock a future where performance, efficiency, and environmental stewardship go hand in hand.

Carbon fiber intake systems revolutionize vehicle performance by offering a superior strength-to-wei…….

Carbon fiber intake systems offer a significant advantage in vehicle design by enhancing stiffness w…….

The construction industry is undergoing a quiet revolution with the adoption of advanced materials l…….

The construction industry is experiencing a quiet revolution driven by carbon fiber intake systems……..

Carbon fiber intake systems offer enhanced UV resistance for automotive and industrial components du…….

Carbon fiber intake systems have gained popularity for their lightweight design and premium aestheti…….

Carbon fiber intake systems are revolutionizing construction by introducing lightweight and durable…….

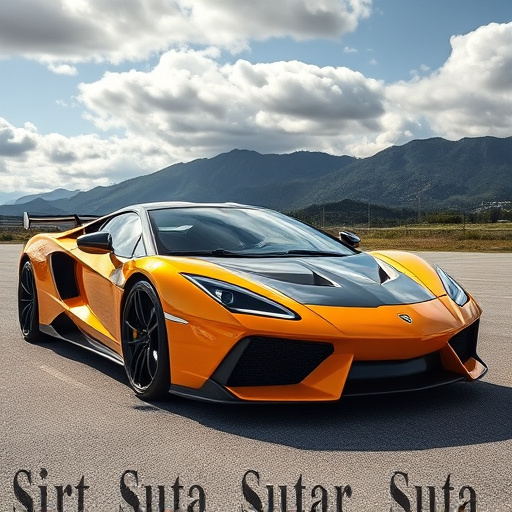

Carbon fiber intake systems have become popular among car enthusiasts looking to enhance both the ae…….

Carbon fiber intake systems offer significant performance advantages in automotive engineering by re…….

Carbon fiber intake systems are transforming the automotive industry by offering significant weight…….